Finishing

Home | Finishing

Anti Bacterial Finish

“Stay fresh. Stay protected. Stay professional.”

In industries where hygiene and presentation are non-negotiable, uniforms and workwear must do more than just look good, they must actively protect against unseen threats. Our Anti-Bacterial Finish integrates advanced antimicrobial technology into a woven fabric to create garments that resist microbial growth and maintain lasting freshness.

By preventing bacteria from settling and multiplying on fabric surfaces, this finish helps reduce odors, discoloration, and deterioration. The result is uniforms that not only look cleaner but also feel fresher, even after long hours of wear in demanding environments.

From healthcare to hospitality, and from industrial sites to corporate offices, anti-bacterial finishes deliver the confidence of cleanliness and the assurance of long-lasting performance.

Oil & Stain-Resistant Finishes

“Protection that works as hard as you do.”

In demanding environments, uniforms and workwear face daily exposure to oil, grease, food stains, and dirt. Our advanced oil- and stain-resistant finishes provide a powerful shield that keeps fabrics looking professional, clean, and durable — no matter the challenge.

By repelling oil and preventing stains from penetrating fibers, these finishes make cleaning easier, extend garment life, and reduce replacement costs. Workers stay confident and comfortable, while businesses benefit from uniforms that maintain a polished appearance shift after shift.

From industrial sites to hospitality floors, oil- and stain-resistant finishes ensure your workwear stands up to spills, resists compromise, and keeps your team looking their best.

Wrinkle-Free Technology

“Stay sharp. Stay professional. All day long.”

In industries where appearance matters as much as performance, uniforms and workwear must withstand long hours, constant movement, and demanding conditions. Wrinkle-free technology delivers exactly that. By applying crease-resistant finishes to cellulose fibers such as cotton, linen, and rayon — fabrics that naturally wrinkle easily — garments retain their smooth, polished look throughout the day.

This advanced finish ensures that uniforms maintain a crisp, professional appearance without the need for constant ironing or touch-ups. Employees can focus on their work with confidence, while businesses benefit from a workforce that consistently looks sharp and well-presented.

Wrinkle-free finishes mean your uniforms don’t just resist creases — they resist compromise.

Soil Release Finishes

“Cleaner uniforms. Easier care. Longer life.”

Workwear and uniforms are constantly exposed to dirt, grease, and everyday stains. Traditional fabrics often trap soil deep within fibers, making cleaning difficult and shortening garment life. Our Soil Release Finishes solve this challenge by engineering fabrics to attract water to the fiber surface during washing. This unique property helps loosen and lift soil, ensuring stains are removed more effectively and garments stay fresh.

By simplifying the cleaning process, soil release technology reduces the need for harsh detergents or repeated washes, protecting both the fabric and the environment. Employees benefit from uniforms that look cleaner and feel fresher, while businesses enjoy reduced maintenance costs and longer-lasting apparel.

Soil Release Finishes mean your uniforms don’t just clean better — they perform better, day after day.

Antistatic Finish

“No sparks. Just safety and comfort.”

In modern workplaces, static electricity isn’t just an inconvenience — it can pose risks to both employees and equipment. Our Antistatic Finish is engineered to provide superior barrier properties on the fabric surface, reducing friction and preventing the buildup of static charges.

By minimizing charge accumulation, this finish enhances safety in environments where sensitive electronics, flammable materials, or precision machinery are in use. At the same time, it improves wearer comfort by eliminating the shocks and cling often associated with static-prone fabrics.

From industrial plants to healthcare facilities, antistatic finishes ensure uniforms deliver both protection and performance — keeping teams safe, comfortable, and professional.

Flame Retardant Finish

“Built-in protection when it matters most.”

Safety is the highest priority in industries where workers are exposed to heat, sparks, or open flames. Our Flame Retardant Finish is engineered to safeguard textiles by reducing their flammability and preventing highly combustible fabrics from igniting. This advanced treatment creates a protective barrier within the fibers, slowing down flame spread and giving workers valuable time to react in hazardous situations.

By combining durability with safety, flame-retardant finishes ensure that uniforms and workwear not only meet strict industry standards but also deliver peace of mind. Employees remain protected without sacrificing comfort or performance, while businesses benefit from compliance, reliability, and a workforce equipped with garments designed for demanding environments.

Flame Retardant Finishes mean your uniforms aren’t just work-ready — they’re life-ready.

Peach / Raising Finish

“Soft to the touch. Strong enough for work.”

Workwear and uniforms are expected to deliver durability and performance, but comfort is equally important. Our Peach / Raising Finish transforms fabrics — whether cotton or synthetic blends — by gently treating them with emery rollers. This process subtly abrades the surface, creating a smooth, velvet-like texture that feels soft and refined without compromising strength.

The result is garments that combine rugged durability with a premium hand feel. Employees benefit from uniforms that are comfortable to wear throughout long shifts, while businesses gain workwear that looks professional, feels luxurious, and stands up to daily demands.

Peach / Raising Finishes ensure your uniforms don’t just perform — they feel exceptional, day after day.

Moisture Management / Wicking Technology

“Stay dry. Stay balanced. Stay protected.”

In demanding work environments, comfort and safety depend on more than just durable fabrics — they require advanced performance technology. Our Moisture Management / Wicking Finish is designed to regulate the interaction between garment and skin, maintaining a controlled moisture balance that keeps workers comfortable and protected throughout the day.

By drawing perspiration away from the body and allowing it to evaporate efficiently, this finish helps stabilize body temperature around 37°C — the natural level for human comfort. The result is a garment that actively reduces the risk of hypothermia in cold conditions and overheating in hot environments, ensuring employees remain focused, safe, and productive.

Moisture Management Finishes mean your uniforms don’t just endure the elements, they help your team thrive in them.

Anti-UV Finish

“Invisible protection. Visible confidence.”

Exposure to the sun’s ultraviolet (UV) rays is one of the most common workplace hazards, especially for employees working outdoors or in environments with prolonged sunlight. Over time, UV radiation can cause skin damage, discoloration, and increase health risks. That’s why modern uniforms and workwear need more than durability, they need built-in protection.

Our Anti-UV Finish is engineered to absorb harmful ultraviolet radiation and convert it into harmless heat, shielding workers from the invisible dangers of the sun. This advanced treatment ensures that fabrics deflect UV rays, reducing exposure and helping protect the skin from potential harm.

As awareness of sun safety grows, businesses are recognizing the importance of protective clothing alongside traditional methods like sunscreen and limiting direct exposure. By integrating UV absorbers directly into the fabric, uniforms become a reliable line of defense, offering consistent protection throughout the day.

From construction sites to outdoor service teams, Anti-UV finishes ensure uniforms don’t just protect workers from the elements — they protect them from the unseen risks of the sun.

Anti-Mosquito Finish

“Protection woven into every thread.”

In tropical regions and outdoor work environments, mosquitoes are more than just a nuisance — they can pose serious health risks and disrupt productivity. Our Anti-Mosquito Finish represents a breakthrough in textile innovation, integrating mosquito-repellent technology directly into fabrics. This advanced treatment provides long-lasting protection, ensuring that uniforms and workwear actively repel mosquitoes while maintaining comfort and durability.

By embedding repellency into the garment itself, workers gain reliable defense without the need for sprays or external solutions. The result is safer, more comfortable workwear that supports employee well-being and keeps teams focused on the job at hand.

Anti-Mosquito Finishes ensure your uniforms don’t just withstand the environment — they protect against it.

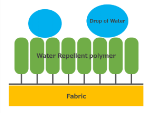

Water Repellent Finish

“Stay dry. Stay protected. Keep performing.”

In the workwear and uniform industry, exposure to rain, spills, and moisture is a daily reality. Ordinary fabrics absorb water quickly, becoming heavy, uncomfortable, and prone to damage. Our Water Repellent Finish changes that by applying a nanoparticle-based compound to the surface of fibers, creating a protective shield that delivers outstanding resistance to water.

This advanced treatment ensures that droplets simply roll off the fabric instead of soaking in, keeping garments lighter, drier, and more durable. Workers remain comfortable and focused, while businesses benefit from uniforms that last longer and maintain a professional appearance even in challenging environments.

Water Repellent Finishes ensure your uniforms don’t just resist the elements — they empower your team to perform at their best, rain or shine.