Fabric

Home | Products | Fabric

Denim

Previously named Grandtex denim world, we have been in the industry for more than 40 years. Our innovative perseverance in keeping up with the global trends and requirements catapults us to be one of the top denim suppliers in the region. Our world-wide elite customers are prominent names in fashion industry such as Levis, GAP, Armani Jeans, etc.

Why our Denim:

Our Experience: Since the establishment of our denim factory, PT Grandtex, in 1976, we have been weaving a wide range of denim and chambray fabrics.

Our factory is located in Bandung, Indonesia with immense capability to weave over 2.5 million yards a year. Our in-house spinning has the capacity produces Ring Yarn and Open End Yarn with Slub and Multicount yarn production.

Our Indigo Dyeing facility for Rope Dye and Loop Dye is expert of producing a wide range of colours - indigo standard, yarn mercerized, dark indigo, double-dip indigo, sulphur bottom, sulphur top, etc.

The worldwide demand for Denim has become one of Lifestyle by Argo Manunggal’s main goals in future development.

We strive in realizing our dream to become the largest integrated textile company in Indonesia. PT Grandtex, shares the same passion to offer excellent service to our existing and potential customers.

Denim is one of the most versatile fabric that transcend across gender, age, race and time. It is perpetually loved and always exists in fashion, be in the upper echelons of designer menswear or on the high streets.

The process of making Denim is similar to the process of weaving other fabrics, The only exception is its requirement to undergo the indigo process at the beginning of the preparation (thread colouring).

The types of raw materials we use to make denim fabrics consist of cotton, rayon, spandex, polyester and slub yarn. Currently, the type of Oz denim that we produce ranges from 4.5 Oz to 13.5 Oz with 2 basic types of the colour blue and black. We have a wide-range world-class quality and qualified resources, as well as sophisticated technologies include:

- Spinning 3000 bale

- Dyeing 1.800.000 YDS

- Weaving 1.500.000 YDS

- Finishing 2.000.000 YDS

- Laser 6000 YDS

High Quality Standards: It starts from our cotton fiber selection which uses avant-garde apparatus. Every production steps are carefully monitored and consistently evaluated up to the end product which required a rigorous QA approval process.

Where We are Stand Out?

Trend & Collection

NATURAL DENIM LOOK

Vintage 501 looks with classic marble character is now attainable through the mechanism on the weaving. It creates the old Gold classic denim fabric piece.

RIGID COLLECTION

A pair of jeans will never fail you.

STRETCH COLLECTION: Maximum comfort for your daily jeans.

Soft-feel and breathable fabric

Experience the good soft hand feel on any surface. Combination of raw material is not enough to provide this kind of smoothness. Air twisted on yarn spinning gives you another level of breathable fabric.

TENCEL DENIM FABRIC

Perfect combination of technology and natural fiber.

a. Lycra Easy Set

b. Specialized in soft feeling fabric

All day light wear

Cross-sectional Weaving Fabric

Sulfur Dyed Fabric

Laser

Grandtex denim is creating new laser printing technology on 100% cotton denim fabric, which bring new perspective of sustainability products. Design pattern and details are transfer via computerized system through indigo burning process to create such beautiful lively dimensional look on clean comfort 100% cotton base. Without any chemical waste and water discharge, we can develop fashion denim wear with the Indonesian rich batik design that are attractive and full of intricate cultural pattern.

grandtexBatikdenim by 100% Cotton USA focus on:

- Sharp optical and gradation shade print

- Fully customized design on soft denim (100% Cotton USA)

- Zero Chemical & Zero Water

Grandtex denim is creating new laser printing technology on 100% cotton denim fabric, which bring new perspective of sustainability products. Design pattern and details are transfer via computerized system through indigo burning process to create such beautiful lively dimensional look on clean comfort 100% cotton base. Without any chemical waste and water discharge, we can develop fashion denim wear with the Indonesian rich batik design that are attractive and full of intricate cultural pattern.

Zero Chemical and Water Waste

Sustainability

Since sustainability derives from the heart of industrial human for a better world, we have identified 4 (four) core Focus inputs that are essential to us and became the foundation of our business.

Our policies, practices, and processes are geared to not only optimize utilization of resources but also to nurture their source. Thus, it ensures that they remain in abundant supply. Our focus is on managing, enriching and obtaining these inputs in truthful manners and thereby making our whole business sustainably sound.

Our Social Responsibility

Our Denim (Grandtex) is in the denim value chain. We create innovative fabric production while remain committed to a vast ongoing sustainability, as well as social and ecological responsibility to the industry. Our responsibility is to create awareness for our customers/consumers on innovative & sustainable products. We have embraced sustainability as a platform for innovation. We leverage the cooperative works between our design, R&D, procurement, sales and production teams and suppliers to create more sustainable products for our customers and to preserve our planets. As a fabric mill; reduction of waste, energy and water conservation, recycling, health matters, safe and healthy working environment are the core of our sustainable strategy. We are continuously implement recycling programs in our production facilities; such as heat, waste water, alkaline, boiler heat, etc.

Today, we are in the position to offer ecocentric products range, such as organic, eco-made fiber, bio-based and recycled materials, as well as cotton.

We communicate our impacts in accordance with our certifications and programs such as ZDHC, CleanChain, Higg Index, GOTS/OCS, GRS, OEKO TEX STANDART100, etc. Our Denim (Grandtex) utilizes the best quality cotton yarns available on the market. We are working hard to acquire more of our materials from sustainable sources such as BCI and Cotton LEADS™. At the same time, we are constantly introducing the new and innovative eco-materials, such as REPREVE® (fiber made from recycled plastic), to produce denim and piece dye in a sustainable manner, without compromising the quality of our products. We have always been mindful of the importance of conducting our productions in a responsible manner. We invest in ethical strategies and actions in every stage of our business to transform our industry into a greener future.

Video & Sosmed

Proses Washing Denim

Rigid Denim

Mens Stretch Denim

Yarn Dyed Denim

Light Weight Denim

Ladies Stretch Denim

Super Stretch Denim

Black Denim

Sustainability

Kids Denim

Performance

Visit Our Website

Welcome to Grandtex denim world. We have been in the industry for more than 30 years. Our innovative perseverance in keeping up with the global trends and requirements catapults us to be one of the top denim suppliers in the region. Our world-wide elite customers are prominent names in fashion industry such as Levis, GAP, Armani Jeans, etc.

Denim is one of the most versatile fabric that transcend across gender, age, race and time. It is perpetually loved and always exists in fashion, be in the upper echelons of designer menswear or on the high streets.

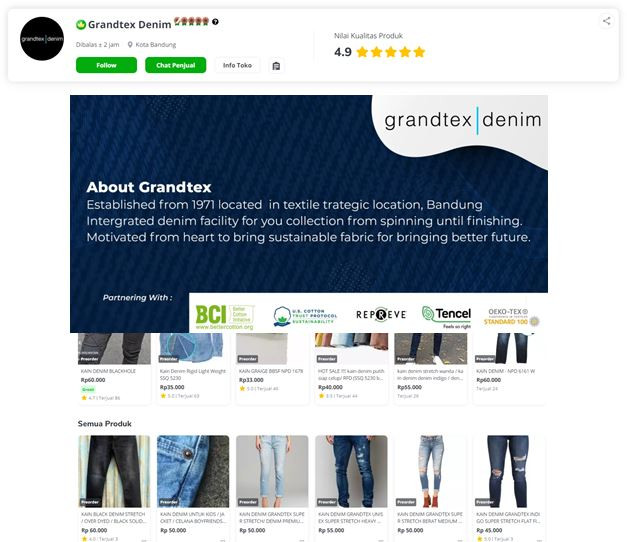

E-Commerce

About Grandtex

Established in 1971, we are located in the well-known strategic location for textile, Bandung.

As an integrated denim facility, we offer our customers from spinning until finishing.

We are passionate in bringing sustainable fabric for a better future.

Keep up with our Social Media :

Tik Tok